🛡️ 30 JOURS DE GARANTIE GRATUITE 🛠️🚚 LIVRAISON GRATUITE VERS L'UE! 🌍👩❤️👨DOUBLE OFFRE : SPÉCIAL SAINT-VALENTIN & DÉSTOCKAGE🌹🐼 SHAN ZU × PANDA ÉDITION LIMITÉE 🌿

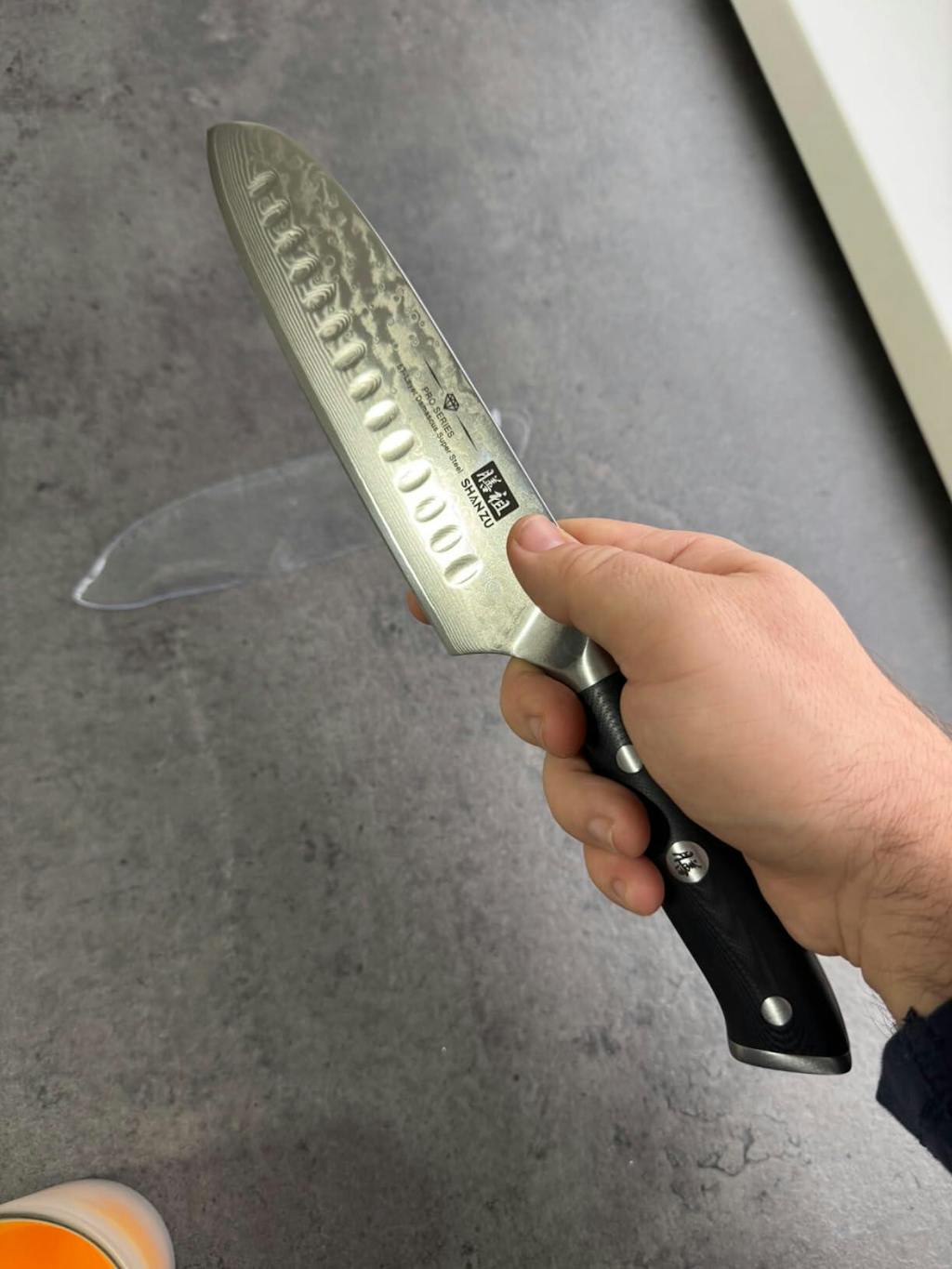

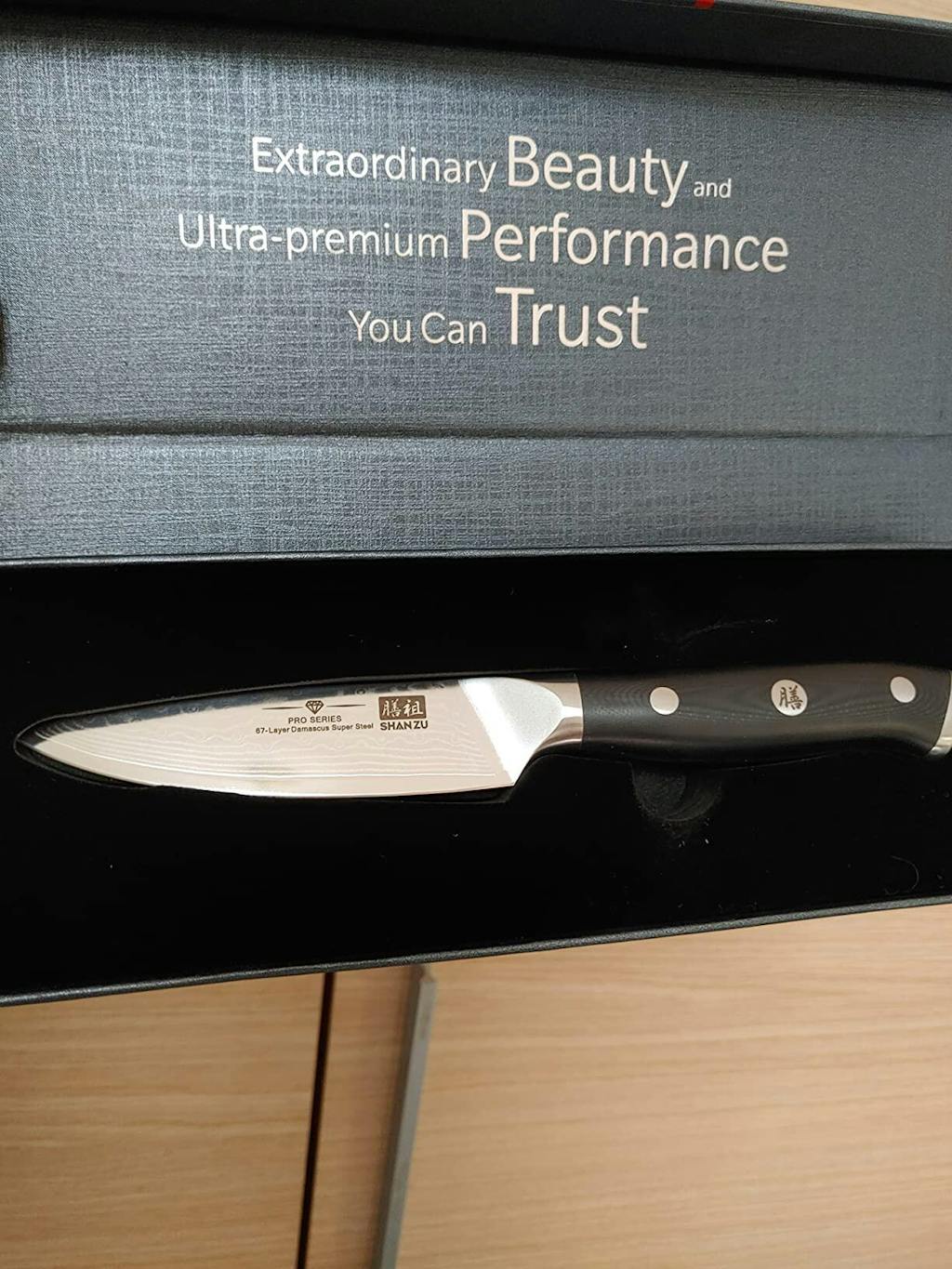

Notre Sélection de la Série Damas

La série de couteaux de cuisine Damascus comprend une variété de couteaux de cuisine, chacun ayant sa propre fonction et son propre style. Chaque couteau est fabriqué à partir de 67 couches d'acier Damas de haute qualité, ce qui donne un motif exquis et unique sur chaque lame et permet de trancher, découper et hacher avec précision et facilité.Let customers speak for us

À propos de SHAN ZU

SHAN ZU se consacre à la création de couteaux de qualité supérieure qui allient fonctionnalité et esthétique. Nos couteaux sont fabriqués avec les matériaux les plus nobles et une technologie de pointe, et sont conçus pour offrir des performances de haut niveau. Nous pensons que chaque cuisine devrait disposer d'un ensemble de couteaux à la fois pratiques et esthétiques. Avec une équipe d'artisans et de designers experts, nous nous engageons à fournir à nos clients les meilleurs produits et services possibles. Découvrez notre passion pour les couteaux et notre engagement en faveur de l'excellence chez SHAN ZU.